Testing, reviewing, quality assurance

IMM electronics GmbH offers you technically sophisticated solutions at the highest level. Requirements that are of the ambient conditions during internal processes are described in all of our procedural, working and testing instructions. In order to also be set up optimally positioned in the future as well, IMM electronics GmbH integrates the core competencies of test equipment construction, test equipment design and creation of test concepts as well as complete test adaptations. The "time-to-market" is thereby reduced for the customer. Individual tests by certified partners round off our solution package for you.

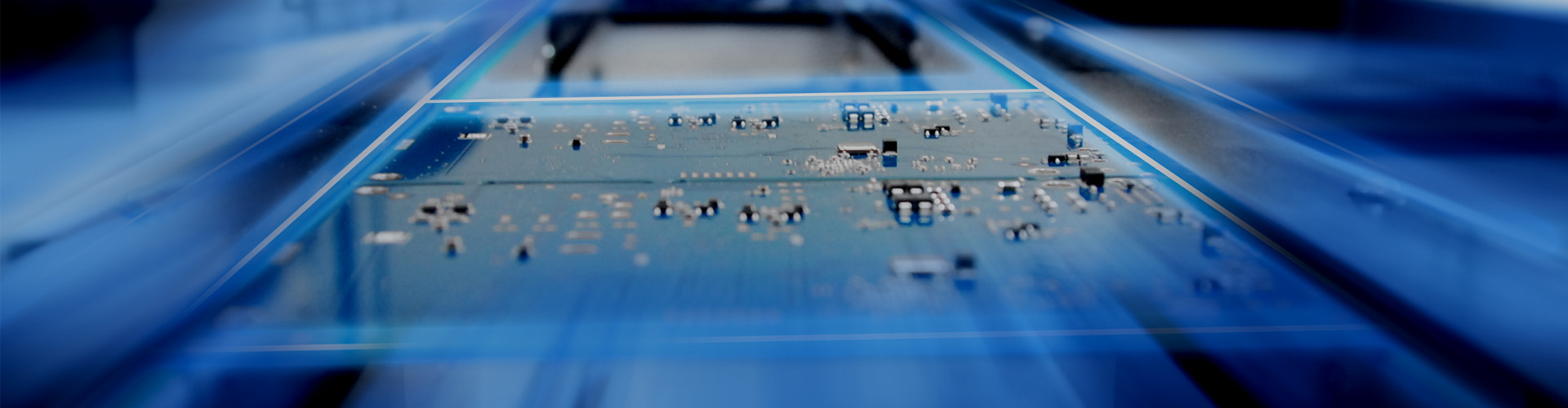

Automatic Optical Inspection system (AOI) - Viscom 3088-II

- Full automatic optical inspection system (AOI) for control of assembled/soldered PCBs

- Orthogonal module with 4 cameras and angular perspective with 8 cameras

- Offline programming

- Check of polarity, soldering and placement of components

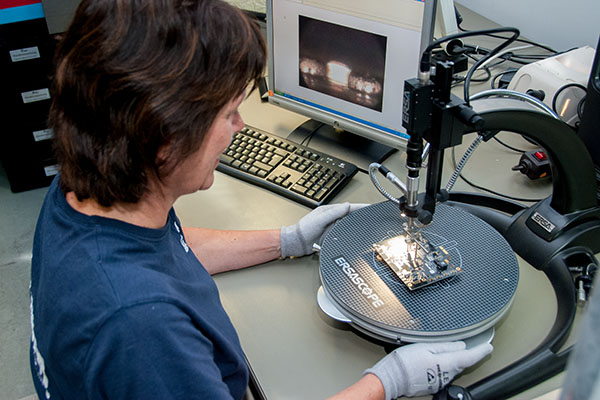

Soldering point inspection system – Ersascope

- Optical analysis of a solder connection up to optical inspection of solder joints under the component

- Versatile, i.e. quality control in different working areas such as receiving area, SMD soldering paste printing, visual testing area or maintenance, repair and operations

- Inspection of hidden solder connections, for example at BGAs, CSPs and FlipChips without destroying the module

Visual inspection - Magnus HD

- Optical visual inspection of the fitted circuit board

- Image resolution HD 720p

- Snapshot function

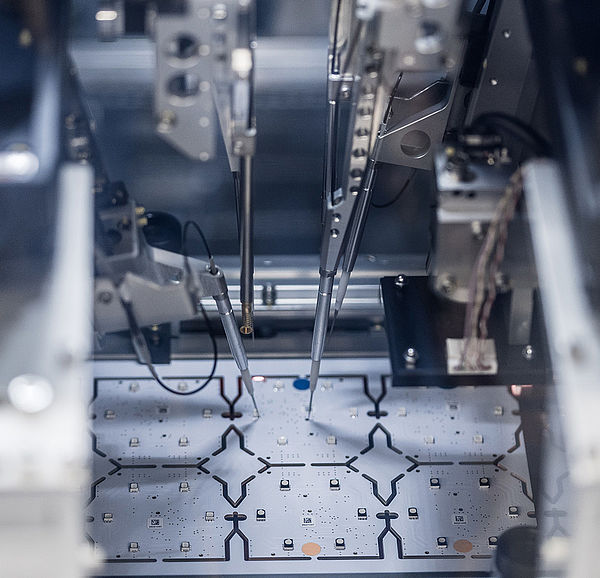

Takaya Flying Probe Tester

- Flying Probe and In-Circuit Tests possible

- Testing of prototypes, pre and small series with average lot size

- Error diagnostic after unsuccessful test

Boundary Scan System Göpel

- Software system Cascon

- JTAG standard IEEE 1149.1 inspection

- Functionality Inspection through following tests:

- Connection test according to network lists

- Test of RAM-components

- Flash memory programming

- Functional test of interfaces and modules consisting of several boards

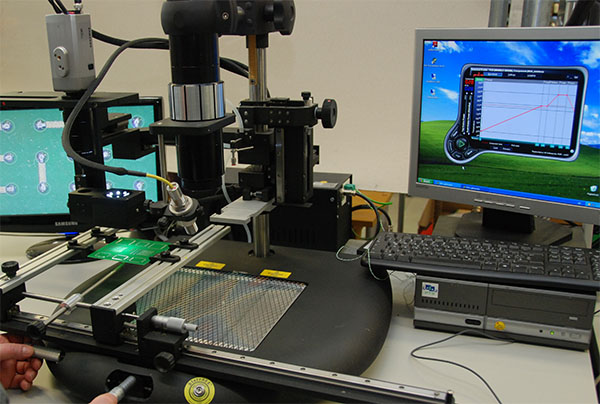

Evertec / Zevac

- Focused IR component heating

- Automatic profile control

- Optical positioning system